Anhui Weiguang Cable Co., Ltd.

National key backbone enterprise of wire and cable industry

Anhui Weiguang Cable Co., Ltd., founded in 2006, is located at No. 21, Meichonghu Road, Shuangfeng Development Zone, Hefei City, covering an area of more than 106,000 square meters. It is a key backbone enterprise in the national wire and cable industry. The company has a registered capital of 360 million yuan and an annual production capacity of about 3.5 billion yuan. There are 295 employees, 68 professional and technical personnel, with strong technical force, advanced production and testing equipment and strong new product development capabilities.

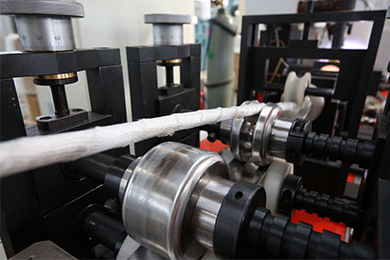

Anhui Weiguang Cable Co., Ltd. is a large-scale enterprise specializing in R&D and manufacturing of wires and cables.

Learn more

The company is mainly committed to the systematic research and development, design, manufacture, marketing and service of various series of high-quality cable products such as overhead conductors, power cables, wires and cables for electrical equipment, and special cables. Products are widely used in electric power, transportation, energy construction and other fields.

Learn more

Since its establishment, the company has attached great importance to product quality and strengthened the quality awareness of employees. It has strong technical strength, professional production equipment and testing methods and a perfect quality control mechanism. The products are sold all over the country and overseas.

Learn more

Phone:13966739709(WeChat)

Phone:13966661192

E-mail:285408654@qq.com

Address:No. 21, Meichonghu Road, Shuangfeng Development Zone, Hefei, Anhui

Copyright © 2021 Anhui Weiguang Cable Co., Ltd. 皖ICP备19001921号-1 SEO